The Grassmayr Bell Foundry in Innsbruck, Austria, is one of the world’s oldest factories, and they do factory tours!

“We think of bells as living things, each with its own personality”, says Monika Unterholzner, whose family, the Grassmayrs have been making bells in Innsbruck since 1599, “and we talk about ‘giving birth’ to them. When the time comes they are drawn out of the casting pit, then when the mold comes off they are grey and dusty just like a baby (vernix), and then we lift them up and give them a smack, and you hear the baby’s first cry”.

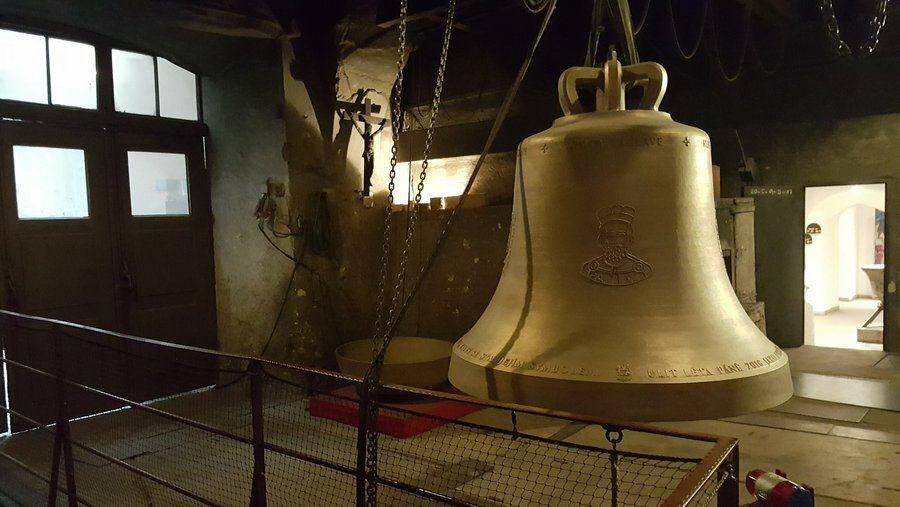

The Grassmayr foundry has given birth to some important and impressive ‘babies’ over the past four centuries. They include the bells of Mount Tabor in Israel and St Catherine’s Monastery in the Egyptian Sinai, the 10-ton “Friedensglocke” (peace bell) in Telfs/Mösern in North Tyrol, and, more recently (and smaller), the 3-ton tubular bell in Aarhus, Denmark – cast for the 2017 European Capital of Culture, and rung, appropriately, to mark the birth of each newborn human baby in Aarhus!

Monika and her family run the oldest family business in Austria, but not the world’s oldest bell foundry. They’ve just moved up a rank since the sad demise of Britain’s oldest and most-famous bell maker, the Whitechapel Foundry founded in 1570, which sadly closed last year (May 2017) after 450 years of giving birth to bells such as Big Ben and the Liberty Bell in Philadelphia. However the “World’s Oldest” title goes to the Italian Marinelli Bell Foundry which dates back to 1339.

How do you make a bell?

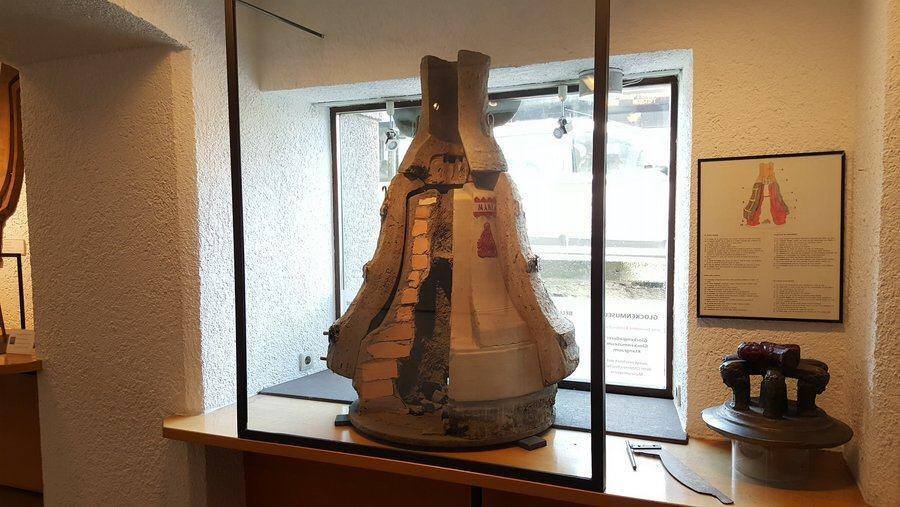

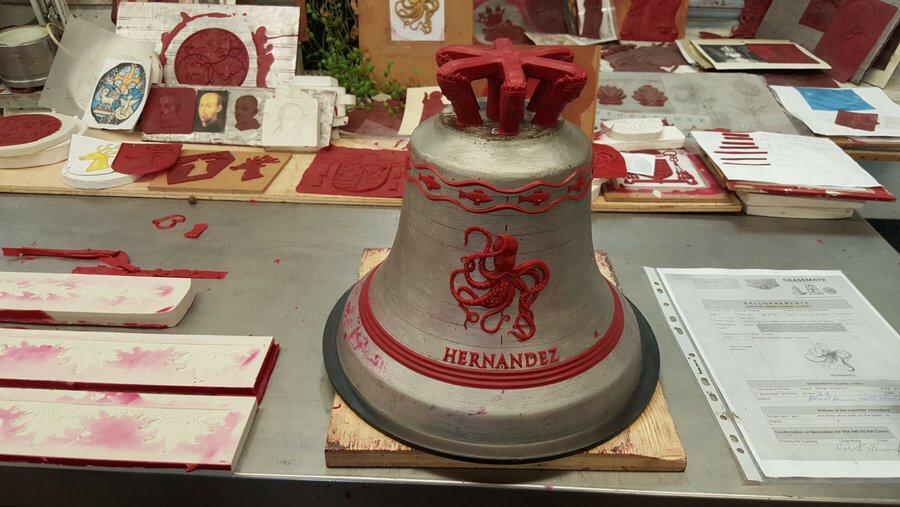

Well, essentially there are three principle bits of information they need to cast a bell – The tone, the size (weight), and the ornaments (what to put on it).

From that they draw a wooden template of the shape of the bell, which is used to create the shape of the ‘core’ (the inner mold) made of clay and other ingredients unique to the bellmaker (everything from horse hair to beer!), and the outer mold which sits on top of the core. It’s into the space between them that the molten metal is poured.

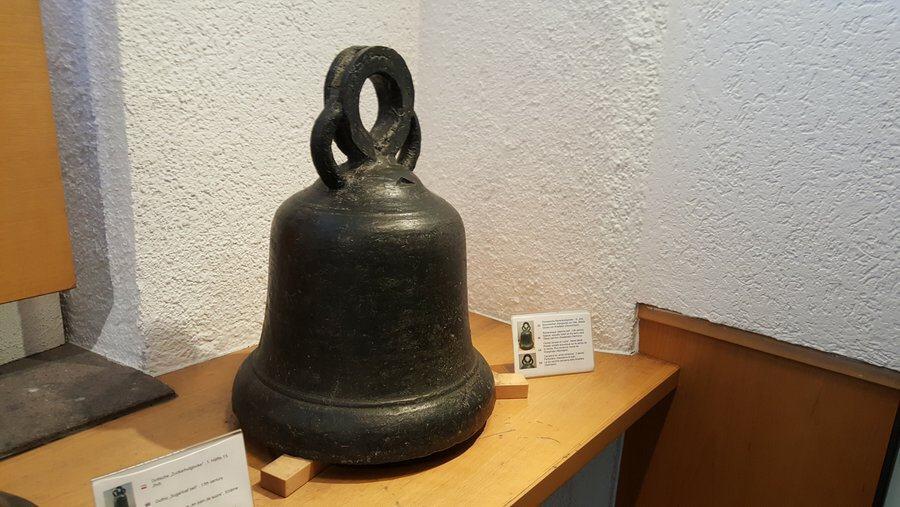

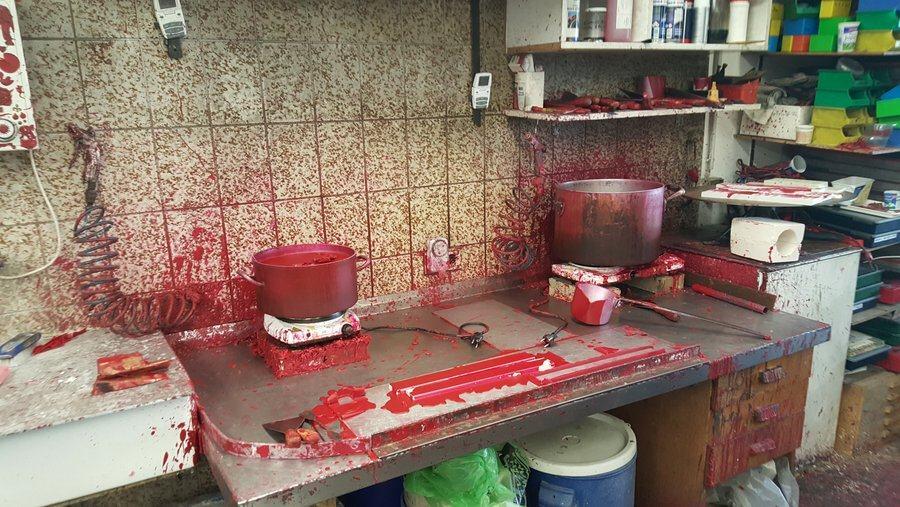

The process of bell-making has changed little over the centuries. Rather, the techniques have been refined incrementally and passed on from generation to generation. As Monika shows me around the foundry, explaining how the molds are made, how the ornaments and intricate decorations are created and added, how the bronze is created and poured at over a thousand degrees centigrade, and how it is cooled over days, I am struck by how often parts of that process are based on ancient family lore, but always double-checked by modern science. The Grassmayr foundry has a longstanding relationship with several universities, so when for example, family lore dictates that the molten bronze should be stirred only with sodden wood from linden trees, they turn to academia to confirm and explain why.

The foundry produces over 300 bells a year, ranging from huge bells like the 25-ton bell recently cast for the Cathedral of National Redemption in Bucharest (the foundry’s 6m casting pit can handle bells weighing up to 37 tons), to small hand-held bells, quite a few of which get sold from the foundry shop to visitors to the museum & on the factory tour!

I’m lucky enough to get a one-on-one tour, but I can see how much effort goes into explaining the bell-making process and the audio characteristics of bells to visitor groups. There’s lots of hands on experimentation for adults and kids to enjoy.

One part of the foundry that is normally ‘off-limits’ to tours is the wax workshop where the foundry artists craft detailed engravings for the bells. The work is too delicate to allow groups of tourists in there, but it’s a shame because it’s a real insight into the care & craft that goes into bell-making.

As artificial intelligence and robotics take over more and more jobs, there is something romantic and reassuring about seeing a manual manufacturing process that has changed little over the centuries, and that is unlikely to be taken over by robots any time soon.

Declaration: I was on a visit to Innsbruck hosted by Innsbruck Tourism. Our city guide mentioned the bell foundry and invited me to have a look. It turned out that she, Monika, was part of the family…. and even has a bell to prove it!

Factbox

Website:

Grassmayr Glockengiesserei

Getting there:

Leopoldstrasse 53, A-6020 Innsbruck

Tirol.

You can walk from the city centre easily.

Museum Price:

Children (under age 6, free) aged 6 – 14: : € 5.00

Adults: € 8.00

Groups / per person (min. 15 people): € 5.00

Family ticket: € 20.00

Guided tours per group (maximum 35 people): € 55.00

Opening Hours:

1000 – 1600 Monday – Friday

1000 – 1600 Saturdays in summer (1 May – 31 Oct)

I really enjoyed the tour. It’s well with the visit if you’re near Innsbruck.