The Antoigné Foundry (Fonderie d’Antoigné) is an industrial heritage centre* run by volunteers of the Antoigné-Chappée Founders Association. It is located on the former site of a large ironworks, originally a small forge established in the 17th century at Antoigné in the commune of Sainte Jamme sur Sarthe, on the bank of the Sarthe river.

The region of Sarthe, with the city of Le Mans in the centre, is well known for its metal industry, and it is no coincidence that the French automobile industry grew up around the city in the late 19th century.

History of the Antoigné Foundry

The location for the forge was chosen because there were charcoal fire pits already there, fuelled with wood from the surrounding forests, the river could provide hydraulic power and transport, and nearby in the commune of La Bazoge there was seam of iron ore that had been mined since Roman times.

The forge produced mostly weapons during the middle ages and slowly expanded, but it grew rapidly after 1855 when Victor Doré built a blast furnace to create products for the local railway industry. Four years later he replaced it with two modern furnaces to re-melt cast iron shipped in from NE France and England, which he then moulded or cast into parts.

Victor Doré’s daughter, Victorine, married her dad’s secretary-accountant, Armand-Alexandre Chappée and the Antoigné ironworks passed into his control in 1867.

Chappée quickly set about reforming conditions at the ironworks. He reorganised shift patterns & working hours; reducing the working day to 11 hours (9 for women). He was one of the new breed of paternalistic industrialists in that era such as Joseph Schneider at Le Creusot, the Michelin brothers at Claremont Ferrand, and over in England, George Cadbury.

By 1889 the factory’s foundry, forge and construction workshops were busy producing water and gas piping, pumps, building and mechanical parts, railway and tramway equipment, track points and crossovers, cranes, bearings, and turntables. All of this was being shipped out on a 2-kilometre steam tramway to join the railway from Le Mans to Caen.

That same year Chappée won the foundry grand prize at the Universal Exhibition in Paris, which inspired him to branch out and start mass producing cast iron radiators.

During the First World War, the Antoigné factory produced grenades and shells. Then, in the inter-war years, after Armand Chappée’s death, his sons took over… and made a mess of things. In 1928 the factory was sold to the Société Générale des Fonderies, who expanded cast iron radiator production, increased the staff to 1,800, and started buying other factories.

That was its peak. The growth of electric heating and more efficient radiator designs, coupled with the company’s reluctance to move into new markets, began a slow and inexorable decline until it finally closed in 1985.

The Antoigné Foundry Heritage Centre

The heritage centre is housed in the former factory canteen, an Eiffel-style iron & brick building that previously served as an electric power station and then a locomotive garage. It was built in 1917, so it was appropriate that the local council who purchased the canteen and the concrete water tower next to it in 1987, renovated it in 2017 – a hundred years later

The role of L’Association des Fondeurs d’Antoigné (Antoigné Foundrymen/womens Association) and their building is to preserve the metallurgical history of the site and the region, and to explain & demonstrate the products and skills that were carried out in this important industry. To that end they have specific themed events, workshops for adults, workshops for children, seminars, conferences, and temporary exhibitions.

On the ground floor are the workshops and demonstration area, and upstairs is where the museum artefacts are displayed.

The regular demonstration is the casting of a tin key ring in the form of a Le Mans 24hr car in the shape of the 24hr track. The Antoigné Foundry was closely associated with the 24hr race and made many of their trophies and signs over the years.

|

|

|

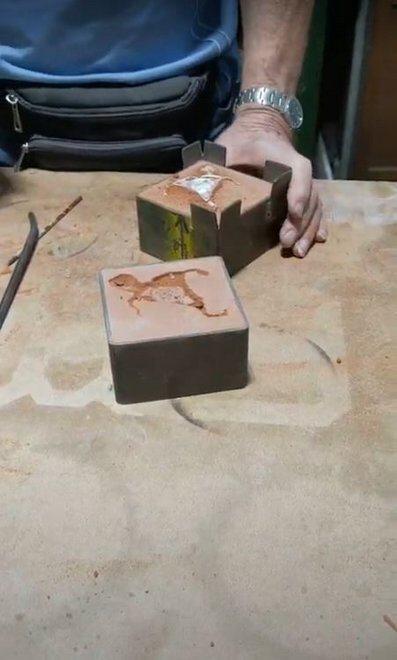

Visitors get to choose their preferred template which is then firmly pressed into tightly packed fine sand in the two halves of a moulding container. A tube is tunnelled into one half before they are joined together and liquid tin is poured through the tube to the moulded cavity in the centre.

When it’s cooled, the container is opened and the key ring is cleaned up and presented to the visitor.

Declaration: I was on a self-driving press trip as a guest of the Pays du Mans tourist office. My visit to the heritage centre was complementary.

* A little like the Metallurgy Museum of the Ardennes

Factbox

Website:

www.fondeursdantoigne.com (Only in French)

Getting there:

2 ZI d’Antoigné

72380 Sainte Jamme sur Sarthe

France

Sainte Jamme sur Sarthe is around 16 kilometres north of Le Mans. It’s roughly a 25 minute journey if you are travelling by car on the D47 from the centre of Le Mans.

See also: Mechtraveller guide to visiting Le Mans

Prices/Visits:

- Group visits on request from May to October. Get in touch by phone (+33 9 63 21 56 83) or email (ass-fondeurs-antoigne@orange.fr)

A Group of up to 20 adults costs 5 Euros per person (children: 2 Euros) for a 2 hour visit which includes a guided tour, a film presentation, and a sand casting demonstration. - The centre is open to individual visitors on the first Sunday of each month. The price is 6 Euros, and there is a 10 Euro option which includes a guided tour of the village. (Accessible to people with reduced mobility.)