British Airways are looking at ways that 3D printing technology could improve punctuality and reduce carbon emissions by bypassing the need to fly spare parts out to its fleet around the world.

The thinking is that 3D printers located at airports around the world, could be used in the future to create aircraft parts, starting with non-critical & non-essential cabin parts such as pieces of tray tables, entertainment systems and toilets. While these components do not impact the safe operation of the flight, they can reduce the number of seats or toilets available for customers and cause delays as engineers wait for the parts to be flown to wherever the aircraft is.

Another benefit is that 3D printers can produce parts that, while as strong and durable as traditional components, weigh up to 55% less. Every kilogram removed saves up to 25 tons of CO2 emissions during the lifespan of an aircraft.

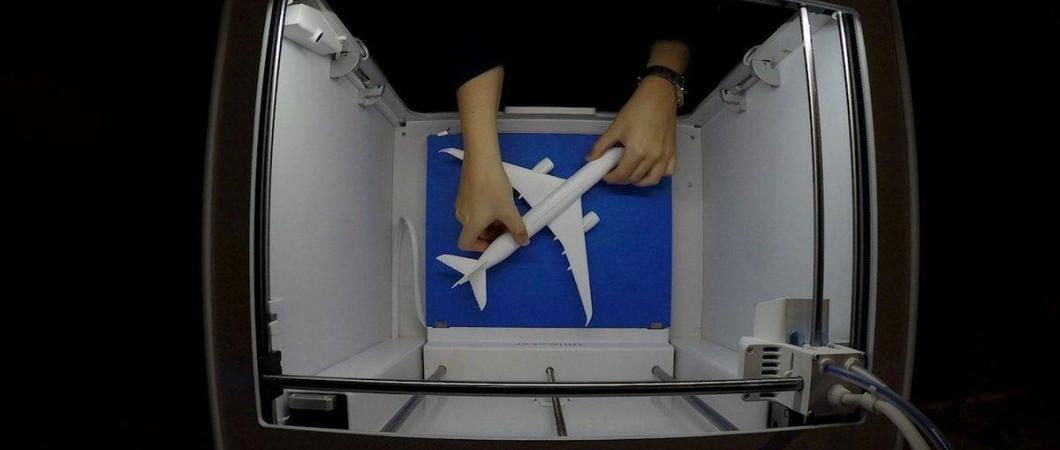

To promote their ideas, they have produced a time-lapse of a model of the airline’s Airbus A350 being printed…

Looking further into the future, BA are also thinking about developments in 3D bioprinting. They are suggesting that within the next decade, biological scanners gathering travellers’ physiological and nutritional needs could suggest food and drink to meet individual requirements and print these on board the aircraft. In addition, their research predicts that jet lag could become be a thing of the past, with 3D bio printers producing personalised health supplements.

British Airways’ top ten predictions for how 3D printing could be used by airline’s in the future:

- Cutlery

- Products for amenity kits, such as toothbrushes or combs

- Tray tables

- Aircraft windows

- Inflight entertainment screens

- Seats

- Baggage containers

- Circuit boards for electrical components

- Flight deck switches

- Aircraft shells

Personally, I’d like to see A LOT of testing before the introduction of windows, circuit boards and aircraft shells!

How do you feel about it?